Oily Water

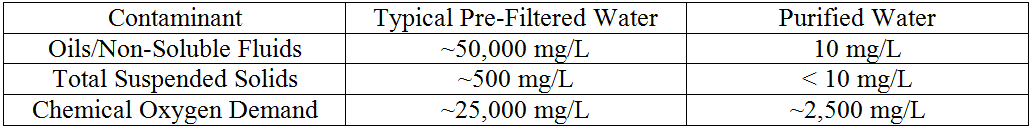

There are a wide variety of applications that use oils and other non-water soluble fluids in their processes, such as such as metal fabrication, metal alteration, petroleum processing, etc., therefore, when water is introduced into this process, the fluids become entrained and ultimately end up in the wastewater stream. Lighthouse has a unique design to address this for recycling and removal that has no moving parts and requires very low operator attention. The process would begin by feeding the wastewater stream into one of our Plate Clarifiers with attached bubble tank. The purpose of the bubble tank is to have an air stream fed into the tank prior to the Plate Clarifier in order to cause the oils in the wastewater to adhere to the surface of the bubbles being created and bring them to the surface of the water for removal. Once the stream has passed through the bubble tank, it would then flow through the Plate Clarifier in order to remove any larger suspended solids. The stream would then be fed through one of our Volcano filters to remove any finer contaminants. Lastly, the stream would flow through Lighthouse recommended reverse osmosis system in order to remove any remaining dissolved solids, contaminants, and non-soluble oils and fluids. The purified effluent stream could then be either recycled back into the process or discharged.