PC™ Plate Clarifier

Parallel Plate Settling Filter

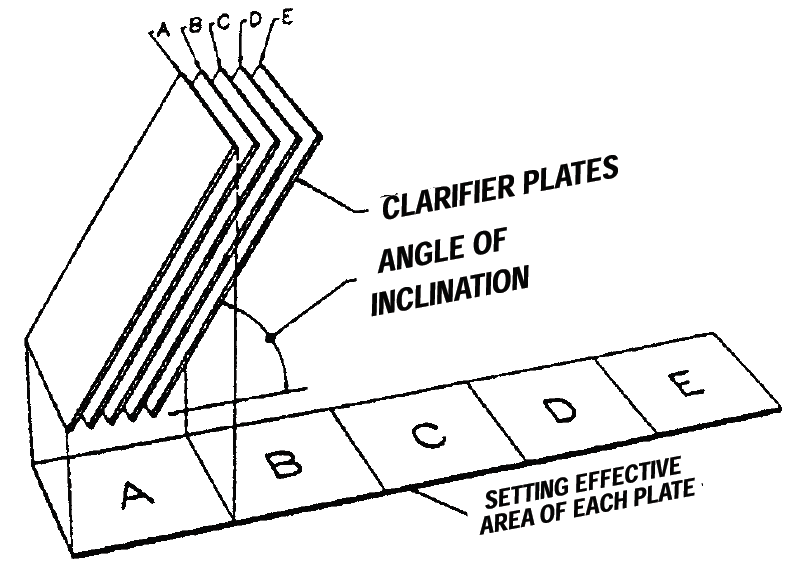

Concept of the Pararell Plate Clarifier.

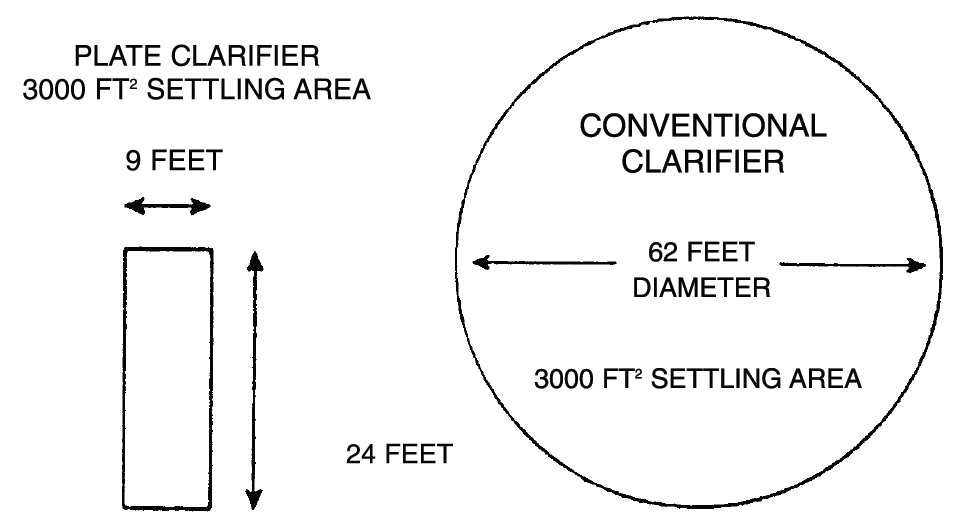

Settling area is the most important design factor in a clarification system. A Plate Clarifier contains a series of inclined parallel clarifier plates. The settling area of a Plate Calrifier is the total of the areas projected on the horizontal plane by the clarifier plates. The overlap of the pararell plates concentrates the effective settling area into a compact space resulting in substantial space savings over conventional circular clarifiers.

Loading rates used in design of the PC™ Plate Clarifier are equivalent to those used for conventional clarification.

Performance is equal to or better than conventional clarification while offering these distinct advantages:

Options

- Flash Mixer & Flocculation Systems

- Chemical Feed Equipment

- Sludge Pump Out & Recycle Systems

- Sludge Thickening & Dewatering

- Polishing Filtration

Comparison for the space requirement for a conventional clarifier and a Plate Clarifeir. Each contains 3,000 square feet of settling area.

Operation

Influent enters the plate clarifier through an inlet nozzle and discharges into a flow distribution zone located across the width of the clarifier. Flow is directed downward, under the parallel plates, then up through the spaces in between the plates. Clear supernatant is collected at the top of the plate area by an effluent launder, equipped with hydraulically designed orifices, to evenly collect the discharge from each plate area. Solids settle on the parallel plates and slide down the plates into a sludge collecting hopper where gravity thickening occurs.

Design

Plates are inclined at a 60 degree angle to ensure that solids do not adhere and block the plate open area. Plate spacing is 2"

Services

- Pilot Demonstration Equipment

- Lab Testing

- Engineered Systems

- Field Service